Things to Note When Investing in Plastic Pyrolysis Plant

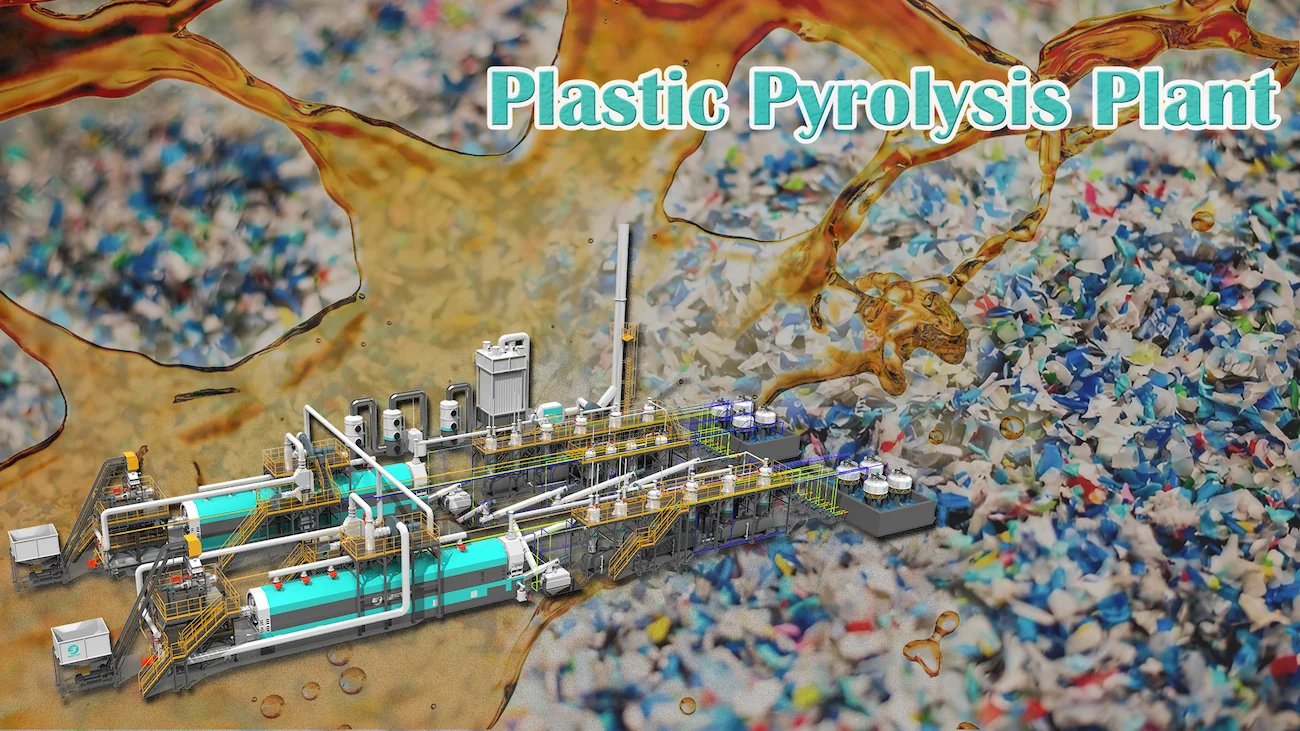

The global challenge of managing plastic waste has opened up opportunities for sustainable solutions, one of which is the plastic pyrolysis plant. These facilities convert waste plastics into valuable products such as fuel oil, carbon black, and gas. Investing in a pyrolysis plant can be lucrative, but success depends on a thorough understanding of several critical factors. Below are key considerations to ensure an informed and profitable investment.

1. Understanding the Technology

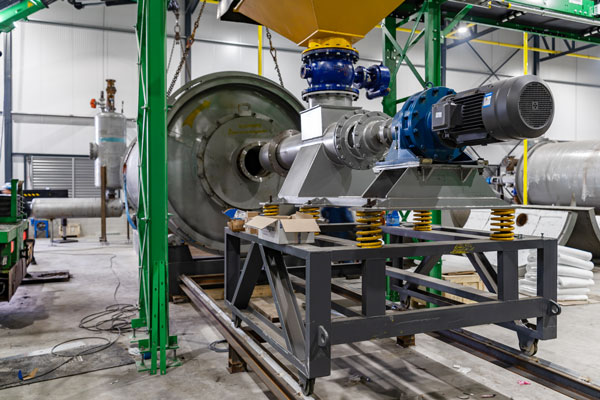

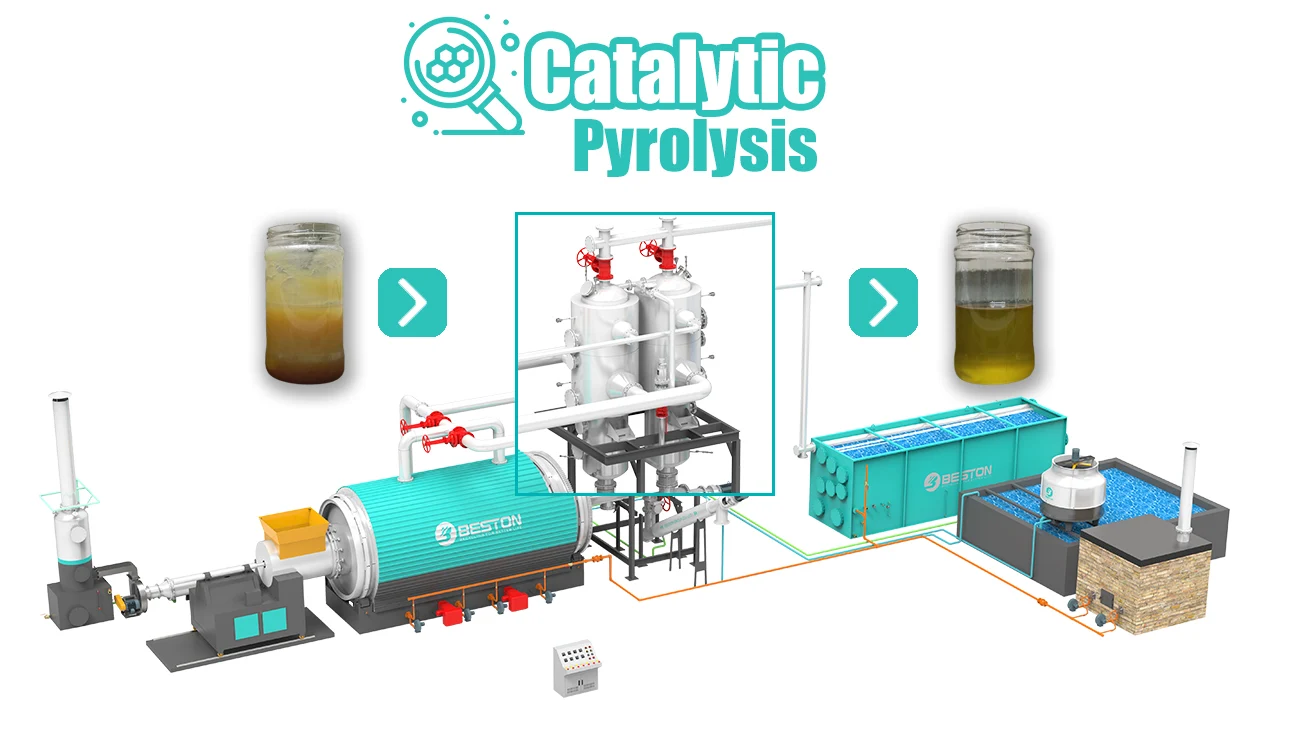

A plastic pyrolysis plant for sale relies on advanced thermal decomposition technology to process waste plastics in an oxygen-free environment. Before investing, it is crucial to understand the types of plastics that the plant can handle and the quality of products it can yield. Not all plastics are suitable for pyrolysis; for instance, PVC and PET may require specific pre-treatment processes. A clear grasp of the technical specifications ensures the plant meets your operational and environmental goals.

Additionally, consider the efficiency of the plant’s design. High-efficiency reactors and heat recovery systems can significantly reduce energy consumption and operating costs, maximizing profitability.

2. Market Demand for End Products

The economic viability of a pyrolysis plant is closely tied to the market demand for its end products. Pyrolysis oil, the primary output, is often used as an alternative fuel in industrial boilers, power plants, and some transportation sectors. Carbon black, another byproduct, is widely used in rubber manufacturing, ink production, and as a reinforcing agent in tires.

Before committing to an investment, conduct market research to assess the demand for these outputs in your target region. Establishing partnerships with buyers or securing long-term contracts can provide financial stability and ensure consistent revenue streams.

3. Compliance with Environmental Regulations

Environmental compliance is a critical aspect of operating a pyrolysis plant. Most countries have stringent regulations regarding emissions, waste management, and energy efficiency. Ensure the plant’s design incorporates necessary pollution control systems, such as scrubbers and filters, to meet these standards. If you want equipment that meets environmental protection policies, Beston plastic pyrolysis plant is a good choice

Failure to comply with environmental laws can result in hefty fines, legal challenges, or even the shutdown of operations. Work closely with local authorities and environmental consultants to secure necessary permits and maintain adherence to all regulations.

4. Location and Infrastructure

The location of the pyrolysis plant plays a pivotal role in its operational success. Proximity to sources of plastic waste, such as recycling centers, industrial hubs, or municipal waste facilities, can reduce transportation costs and ensure a steady supply of raw materials.

Additionally, evaluate the availability of utilities such as water, electricity, and natural gas, which are essential for the plant’s operation. A well-connected location with access to roads, railways, or ports facilitates the transportation of raw materials and finished products, enhancing logistical efficiency.

5. Cost Analysis and Budget Planning

The initial investment in a pyrolysis plant includes the pyrolysis machine price, land acquisition, construction, and installation. Operating expenses, such as labor, maintenance, utilities, and raw materials, must also be factored into the financial plan.

When analyzing costs, consider the plant’s capacity and scalability. A larger capacity plant may require a higher upfront investment but can yield greater long-term returns. Similarly, modular designs allow for future expansion, accommodating increased production demands as the business grows.

6. Supplier Reputation and After-Sales Support

Selecting a reliable equipment supplier is vital for the plant’s performance and longevity. Research the reputation of potential suppliers by reviewing their track records, client testimonials, and case studies. Ensure that the supplier provides comprehensive after-sales support, including installation, training, and maintenance services.

A reputable supplier will also offer warranties and guarantees on equipment, providing assurance of quality and performance. Building a strong relationship with the supplier can simplify troubleshooting and upgrades pyrolysis technology in the future.

7. Waste Management and Byproduct Utilization

Efficient management of byproducts, such as non-condensable gases and solid residues, is essential for sustainable operations. Non-condensable gases can often be recycled within the plant as a supplementary fuel source, reducing energy costs. Solid residues, such as char, can be processed into valuable products like activated carbon or construction materials.

Understanding the full potential of byproduct utilization not only enhances profitability but also minimizes environmental impact, aligning the business with circular economy principles.

8. Risk Assessment and Mitigation

Investing in a pyrolysis plant involves several risks, including fluctuating market prices for end products, changes in regulations, and potential technical challenges. Conduct a comprehensive risk assessment to identify potential vulnerabilities and develop mitigation strategies.

For instance, diversifying the plant’s product portfolio by processing different types of plastics or exploring alternative markets can reduce dependency on a single revenue stream. Regular maintenance and staff training also ensure smooth operations and minimize downtime.